I led 0 to 1 Product Design at Autodesk to create, test, & ship a 3D printer that delighted users by integrating the hardware, software, & materials into a seamless experience.

Roles:

-

- Principal UX Designer

- Co-led the human-centered design community in SF

- Leader of XD (Experience Design) Communications

- Co-led the Customer Champions team

Responsibilities:

-

- Lead intensive user & client research studies

- Guide product development with detailed, research-based product specs & interactive prototypes

- Manage key accounts, including Intel, Industrial Light & Magic, Smithsonian Institution

- Create user-friendly product documentation

Results:

-

- Guided the product design from concept through to international distribution

- Led the design / redesign of > 1,000 UI elements

- Assured the delivery of quality products & upgrades by partnering with the engineering & QA teams

- Won Autodesk Foundation's Impact Peer award

The Problem / Opportunity

In early 2014, the promise of 3D printing far exceeded its actual rewards. The hype cycle had wildly inflated the public's imagination about what this technology could achieve.

"THIS MACHINE WILL CHANGE THE WORLD," declared Wired Magazine with evangelical zeal. Its cover showed Bre Pettis (the founder of the most popular consumer 3D printer), holding one of his world-changing MakerBots.

In stark contrast to the hype, many of the early adopters of 3D printing were having miserable experiences – print failure after print failure.

3D printing customers were toppling off the peak of inflated expectations down into the trough of disillusionment. They needed a lot of help up the slope of enlightenment to reach the plateau of productivity.

The Mission of Our Product

I joined an agile R&D team (which literally included rocket scientists). We defined the following mission for our product:

Transform 3D printing from a failure-prone & frustrating experience to a productive & delightful one for 3D printing professionals.

This was no small task, given the multiple points of failure across the interdependent domains of software, hardware, & printing materials.

Our team's strategy was to create an ecosystem in which we seamlessly integrate the software, hardware, and materials of the 3D printing process.

We called ourselves the Integrated Additive Manufacturing team.

From the ground up, we created the software, hardware, and materials of what ultimately became Autodesk's first professional DLP 3D printer.

We named it Ember.

The Initial Research Phase

As the Lead UX Designer, my first task was to spearhead the rigorous research that would lay the foundation for the design of our product, with the understanding that research would (of course) need to be an ongoing process.

The research phase primarily involved:

-

- Competitive analysis - Studying and documenting the strengths & weaknesses of the leaders in the field, including FormLabs, EnvisionTEC, 3D Systems, & DWS

- Task analysis - Breaking the overall 3D print-prep, printing, and finishing process down to their sub-tasks, and documenting the flows

- Ethnographic research & contextual inquiry - Traveling to 3D printing labs, observing people in their work environments, and documenting their processes

A technician does finishing work on 3D prints in a dental lab in New Mexico that I studied early in our early generative research phase.

Designing Ember's Front Panel

As the human-machine interface that would enable users to control their 3D printers, and which would provide essential feedback about the status of the printing process, Ember's front panel would ultimately create an experience of either easy utility or frustration. Therefore, special care was given to its definition, interaction design, and hardware design.

Analysis of our research combined with our strategic goals to shape the definition of its many product requirements.

Key requirements for Ember's front panel included:

-

- It shall allow the user to easily control all phases of the printing process

- It shall be able to operate while the user is wearing protective gloves

- It shall provide feedback about the status of the print that's visible from a distance of up to 20 feet

- It shall place a load that is within the functional capacity of the microprocessor

- It shall have as few buttons as possible without compromising its usability

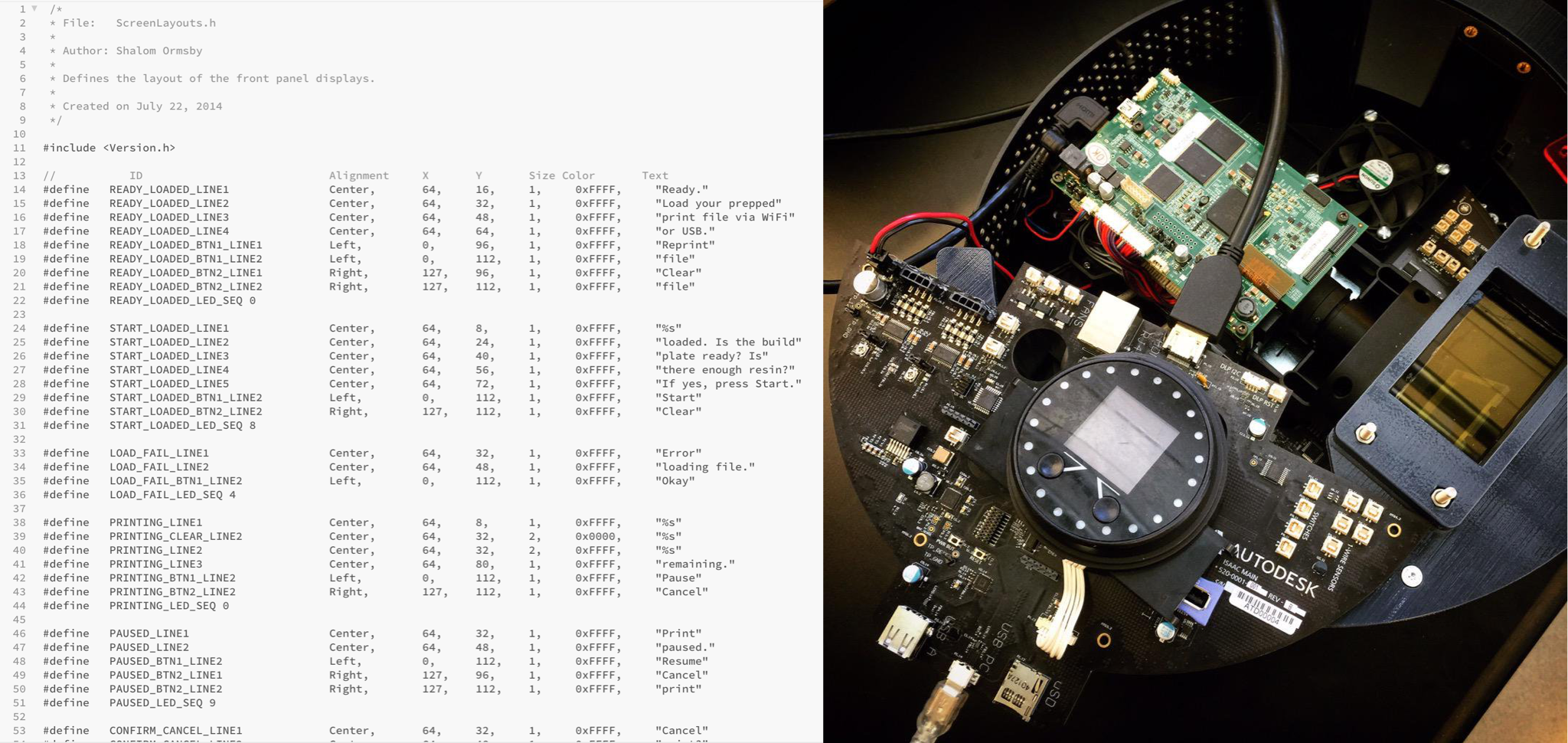

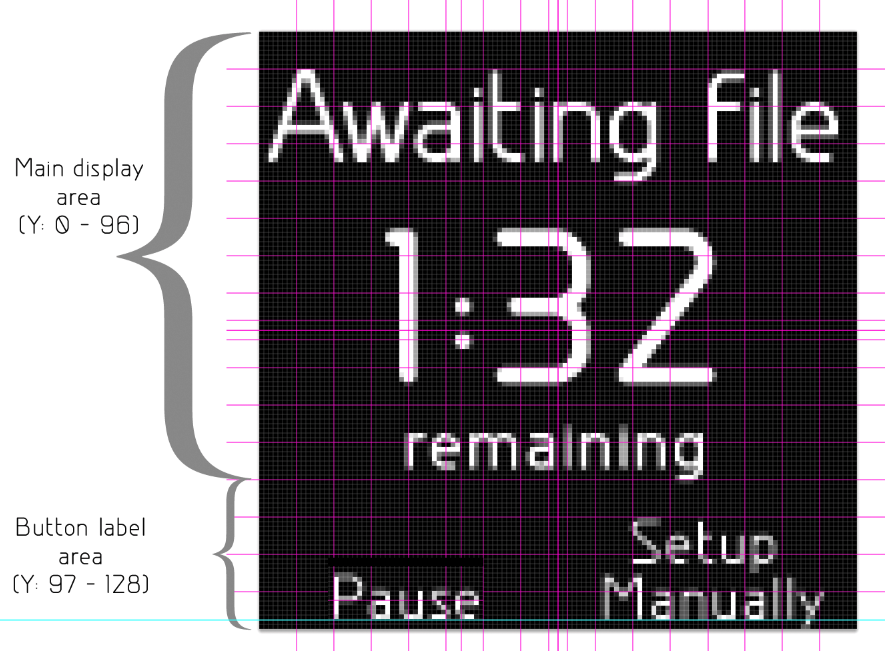

Pixel-placement guidance for the content to display on the control panel's OLED screen, including the main display area and the dynamic labels for the soft keys.

Based on my understanding of our target user's needs and behaviors, I designed the overall concept of the front panel – a central screen with two buttons, encircled by an array of animated LEDs that provide feedback about the key states of the printer, including:

-

- System starting up

- Loading print data

- Ready to print

- Print % complete

- Error

While the industrial designers further developed this concept into production-ready plans, I worked with the engineers to define and encode all of the states and sub-states into what would become Ember's embedded system.

Designing for Sustainability

From the onset of the design process, I collaborated with sustainability experts at Autodesk and beyond to minimize the environmental impact of manufacturing and operating Ember.

Our key sustainability initiatives included:

-

- Collaborating with UC Berkeley's Center for Green Chemistry and The Biomimicry Institute to support the development of nontoxic printing materials that function like photopolymers

- Analyzing & working to minimize Ember's overall power consumption

- Designing for repariability & easy disassembly

- Identifying sustainable packaging materials (instead of typical petroleum-based packaging)

In recognition of my sustainable design work for Ember, I was honored to receive Autodesk Foundation's Impact Peer Award.

Integrating Software, Hardware, & Materials

Did we succeed in our ambition to create a seamless 3D printing experience for our users? Once we started shipping our product, this question was top of mind for our whole team, as well as for our executive stakeholders.

We looked to our users. I closely monitored our online forum and customer support tickets. Over time, as the data points grew, we started recognizing patterns.

We had not managed to completely eliminate 3D print failures. We were able to identify the root cause of most failures: suction and adhesion forces on the PDMS membrane (the active printing surface), resulting from chemical reactions in the photopolymerization process.

This problem was not unique to Ember. In fact, most stereolithography printers struggled with this issue, and the larger the surface area of the print, the larger this problem became.

We explored numerous strategies to increase Ember's printing success rate, including:

-

- flagging issues in the print preparation software that would likely cause the prints to fail, and offering suggestions to fix them before running the print

- developing a closed-loop control system

- altering the chemistry of the resin

- developing an enhanced peeling system

We had a lot of ground to cover in order to achieve our ultimate goal of making 3D printing reliable and delightful for our target users. Our VP created a strategic vision over the course of the following 5 years – 5 generations of printers would build up to our ultimate goal of offering seamless, reliable, fully-automated 3D printing – "lights-out additive manufacturing production." However, just as this plan had been formulated, our CEO departed, and with no further executive support for our product, Ember was end-of-lifed.

Growing the Design Culture at Autodesk

In addition to my product design work at Autodesk, I was an active member of Autodesk's cross-divisional human-centered design community and served as the leader of several design teams, including:

-

- Co-leader of the San Francisco human-centered design community, SF LUMA

- Leader of the XD Communications team

- Manager of the SF risograph printer

As a passionate supporter of Autodesk's mission to "Imagine, Design, & Create a Better World," I was honored to design the event poster for a presentation by philanthropic artist, Brian McCarty, who work was helping raise awareness for UNICEF's #ChildrenInWar campaign.

I also gave numerous presentations about the open source bionics work of The Luke Hand team (scroll down for more info about this).

Autodesk Team Feedback

"Shalom is one of the most thoughtful, intelligent and driven designers I have had the chance to work with. When we worked on Ember together he thinks of the user's experience and needs throughout the product design process and isn’t afraid to stand up for what he thinks is right, and backs it up with data. His work was professional, innovative and focused on the problem at hand and finding the right solution without cutting corners. Shalom's passion for design is infectious, and I hope I have the opportunity to work with him on future projects."

- S. B., Lead Product Designer

"Working with Shalom was one of the highlights of my time on the Autodesk Hardware Team. His positive attitude is contagious and always made the lab a fun and welcoming environment. As the voice of reason in a sea of engineers, Shalom always kept us on track by ensuring our design efforts brought value to the customers. Shalom has an innate ability to discover and understand people's needs, a passion to design delightful experiences for them, and a gift of working with a team to accomplish this."

- D. P., Engineer